Understanding the Chlor-Alkali Process: A Cornerstone of Modern Chemical Industry

Understanding the Chlor-Alkali Process: A Cornerstone of Modern Chemical Industry

Chlor Alkali

The chemical industry is vast and intricate, encompassing a myriad of processes and products essential to our daily lives. Among these processes, the Chlor-Alkali process stands out as a fundamental method used to produce chlorine, caustic soda (sodium hydroxide), and hydrogen from salt solutions. This article delves into the significance of the Chlor-Alkali process, its industrial applications, and its environmental impact.

What is the Chlor-Alkali Process?

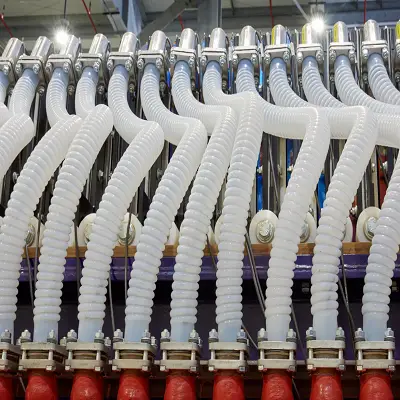

The Chlor-Alkali process is an electrochemical procedure used to break down sodium chloride (NaCl), commonly known as salt, into chlorine gas (Cl₂), sodium hydroxide (NaOH), and hydrogen gas (H₂). This process occurs in an electrolytic cell, where an aqueous solution of salt is subjected to an electric current. Chlorine is released at the anode, while sodium hydroxide and hydrogen are produced at the cathode.

Production Methods

There are three main methods of producing chlorine and caustic soda through the Chlor-Alkali process:

-

Diaphragm Process: This method uses a diaphragm to separate the anode and cathode, preventing the reaction between chlorine and sodium hydroxide. The final product contains traces of salt.

-

Membrane Process: A more modern approach, this method uses a cation-exchange membrane to produce high-purity sodium hydroxide. This process is considered more efficient and environmentally friendly than the diaphragm process.

-

Mercury Process: Now declining due to environmental concerns, this method uses mercury as a cathode. The mercury reacts with sodium to form an amalgam, which is later decomposed to release sodium hydroxide.

Environmental Impact

While the Chlor-Alkali process is vital to the chemical industry, it poses environmental challenges. Chlorine production, for example, requires careful emission control to prevent pollution. The gradual shift from mercury-based processes to more environmentally friendly methods like the membrane process is a response to growing environmental concerns.

Moreover, the energy efficiency of the process is a major issue. The production of chlorine and caustic soda requires a significant amount of electrical energy, prompting the industry to seek ways to reduce energy consumption and minimize the carbon footprint.

Industrial Applications

The products derived from the Chlor-Alkali process are ubiquitous in industry, serving a wide range of applications:

Chlorine

Primarily used in the production of PVC (polyvinyl chloride), solvents, bleaching agents, and in the disinfection of drinking water.

Hydrogen:

Used as a reactant in various chemical reactions, such as ammonia synthesis, and as a clean energy source in fuel cells.

Sodium Hydroxide (Caustic Soda):

Essential in the paper industry, aluminum production, petroleum refining, and in the manufacture of chemicals like soaps and detergents.

Conclusion

The Chlor-Alkali process is a cornerstone of the chemical industry, providing essential materials for a multitude of sectors. However, its environmental impact requires continuous attention, with a transition toward cleaner, more sustainable technologies. Understanding this process and its implications is crucial as we look to a future where the chemical industry can meet society’s needs while minimizing its impact on the planet.

© 2024 All Rights Reserved.